ULTRASONIC TANKS FOR CLEANING AND SURFACE FINISHING APPLICATIONS.

The T-25 tank, combined with our range of detergents, allows a perfect cleaning treatment of the immersed parts, removing any residual dirt. An optimal combination of the ultrasonic generator parameters (power, frequency and modulations), treatment time and temperature deliver results that would otherwise be impossible with conventional washing systems.

Ultrasound cleaning is a state of the art technology that involves high power cavitation diffusion in a liquid solution. As of today, it represents the only means to satisfy some the most challenging and complex requests for the cleaning of mechanical parts, objects with a complex shape, professional, medical and industrial tools. Combine our ultrasound tanks with an adequate washing temperature and detergent and your parts and objects will shine like new.

Ultrasonic power is generated by a group of piezoelectric transducers which, powered by electricity with appropriate power and frequency, convert it into vibrational mechanical energy. This generates millions of microscopic bubbles under vacuum that implode in a targeted manner due to the pressure changes generated by ultrasound, removing dirt particles.

Power and frequency are chosen based on the material of the items and the size of the ultrasound tank: small and delicate materials like eyewear, jewellery, gold and medical equipment will generally be treated at a low power and high frequency, whereas resistant and bigger mechanical parts will require higher power and lower frequencies. Typically, the frequencies used in these kinds of applications vary from 22KHz to 60KHz.

OUR ULTRASOUND WASHING SYSTEM, RESISTANT AND INNOVATIVE, IS EQUIPPED WITH A GENERATOR OF OUR OWN PRODUCTION WHICH GUARANTEES HIGH PERFORMANCE BY USING SPECIFIC MICROPROCESSORS FOR TRANSDUCER CONTROL, ALLOWING FOR OPERATIONAL PARAMETER SETTING AND ADDITIONAL FUNCTIONS. UPON REQUEST SPECIFIC BEESPOKE FUNCTIONS CAN BE ADDED.

OUR LABORATORIES ARE AVAILABLE FOR TESTING ON THE PARTS OF INTEREST TO YOU: CONTACT US TO ORGANIZE A DEMONSTRATION!

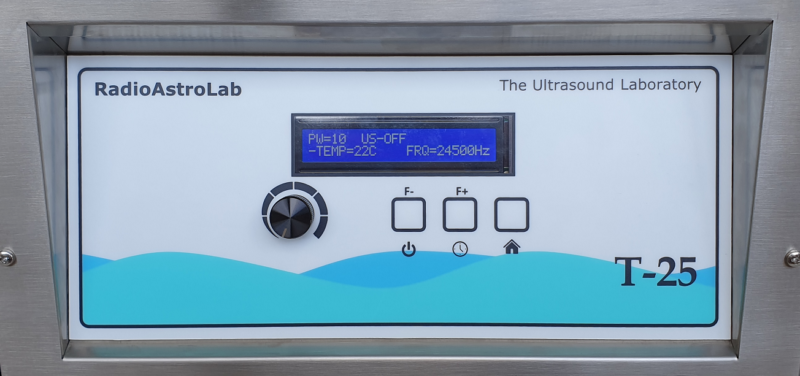

THE CONTROL PANEL

The T-25 tank control panel includes:

- Knob for power variation (and other parameters when the system is in programming mode):

- START-STOP button for ultrasounds; In frequency setup mode it decreases the value.

- TIMER SETTINGS: button for TIMER activation and automatic stop; in frequency setup mode it increases the value.

- HOME button to access parameter setting mode, including TEMPERATURE regulation.

- LCD display (backlit, with white digits on blue background) for viewing operating parameters.

GENERAL CARACHTERISTICS OF ULTRASOUND TANK T-25

- Machine made in stainless steel, robust and easy to clean.

- Capacity: 25-28 litres.

- External dimensions: (720 x 430 x 330h) mm.

- Internal dimensions of the tank: (450 x 350 x 200h) mm.

- Weight (without liquid): approximately 25 kg.

- Single-phase power supply: 230 Vac – 50/60 Hz.

- Electric power of US generator: 700 W (nom.value).

- Electric power of the liquid heating system: 900 W (nom.value).

- Central frequency of the US generator (programmable): 23.5 kHz – 25.5 kHz.

- Continuous variation of the US power supplied with potentiometer.

- Treatment time programming from 1 to 60 minutes.

- Real-time measurement of the temperature of the washing liquid.

- Washing liquid heating (programmable from 20°C to 80°C).

- Automatic modulation of the operating frequency (SWEEP) for optimal distribution of the ultrasonic field inside the tank.

- No.7 high-performance piezoelectric transducers: maximum US power density inside the tank.

- Backlit LCD display for viewing the status and operating parameters, keyboard for commands and parameter programming.

- High-performance electronic generator suitable for intensive use.

- Automatic forced ventilation system for the US generator.

- Liquid drain tap.

- Stainless steel object holder basket.

- Supply of specific detergent for the custormer’s application.

- Our tank is classified, upon request, in the 4.0 industry category, as it is compatible with remote control and setting (via ethernet) of certain parameters.

- Upon request it is also possible to implement specific functions for bespoke applications.

POSSIBLE APPLICATIONS

Our ultrasound cleaning system can be use to clean almost everything. The following is only a list of the most frequently treated objects:

- Plugs, arrays, drills and cutters;

- Carburettors;

- Jewellery (gold, silver and platinum);

- CD’s and DVD’s;

- Medical equipment;

- PCB’s;

- Motor components (bikes, motorbikes, cars and more);