ULTRASONIC GENERATORS FOR CLEANING AND SURFACE FINISHING APPLICATIONS.

An innovative microprocessor technology optimizes the piloting of the transducer: reliability, operational precision and flexibility of use in the complete programmability of its functions are the strengths of our control boards.

All our products are customizable, as both software and hardware are made by us. Once the customer has indicated the main characteristics of the transducers to be controlled (number, power and frequency, double or single ceramic, how are they fixed on the tank…), we will identify the most suitable electronics for his application and, if necessary, make the necessary changes to optimize the piloting.

If requested, we can supply transducers, otherwise we characterize those sent by the customer. It is our practice to request (only at the start of the work and one-off) the customer to send the bath / tubular / plate to be checked, in order to be sure to deliver the best product to the customer for its application.

Write us and we will recommend the product that best suits your needs: marketing@radioastrolab.it.

or

OPEN THE CATALOG

OUR PRODUCTS

We can supply our generators in the following versions:

KIT VERSION (Ultrasound Generator + Interface)

The ideal control solution for those who want a complete and immediate generator, easy to install: the generator and the interface board are both boxed in industrial containers, ready to be inserted in your tank. The interface includes an NTC temperature probe.

Based on the required power, the following versions of kit are available:

- RAL700S generator with the RAL250 interface (up to about 2000W, plastic case of generator).

- RAL700S_A generator with the RAL250 interface (up to about 2000W, aluminium case of generator).

- RAL151S generator with the RAL240 interface (max 400W, plastic case of generator).

The possible management of a level sensor is also envisaged if the customer’s tank has such a sensor. In this case, the models are:

- RAL700SL generator with the RAL250L interface (up to about 2000W, plastic case of generator).

- RAL700SL_A generator with the RAL250L interface (up to about 2000W, aluminium case of generator).

- RAL151SL generator with the RAL240 interface (max 400W, plastic case of generator).

The easy-to-use interface has everything needed to manage the most frequently used parameters in an ultrasonic tank:

- knob for immediate variation of the power (and other parameters, when the system is in programming mode);

- button for activating the solenoid valve for draining the liquid from the tank (only in the RAL700S and RAL700S_A version);

- START-STOP key for the ultrasound treatment;

- TIMER key;

- HOME key to access the parameter selection and programming mode;

- LCD display (backlit, with white characters on a blue background) for viewing the operating parameters.

It is also possible to set the working frequency and the desired temperature in the washing tank, in addition to the early switching on of the resistances.

The system also returns the most important alarm / failure signals for optimal management of the washing system.

For larger systems and therefore greater powers, we are available to evaluate together with the customer the supply of a kit consisting of several generators controlled by a single interface (in the electrical panel version). For high-power systems, the generators can also be configured with a three-phase power supply.

COUNTER TOP VERSION

The benchtop generator is the ultrasound control solution for those who want a complete and immediate generator independent of the tank. All the tank manufacturer will have to do is connect the transducer group (operating in the 22-60 kHz band) to the generator and power the system (230 Vac, 50/60 Hz).

Based on the required power, the following models are available:

- SHELL generator (max 400W).

- TRITON generator (max 400W)

- TRITON_SCAN generator (max 400W).

- RAL400 generator (max 400w, for narrow-band piezoelectric transducers – Sonotrodes).

- CORAL generator (max 2000W).

The TRITON generators series has been developed to power transducers inserted in high-frequency vibrating screens (from 20 kHz up to 60 kHz) for the food and chemical industries. The ultrasonic power in the vibrating screens is generated by one or more piezoelectric transducers which, powered by the TRITON generator, is converted into vibrational mechanical energy. The power and frequency of work are chosen according to the specific operational needs.

The TRITON_SCAN generator receives the commands necessary for operation from an external controller via an asynchronous UART serial peripheral with two-wire RS485 format. The simplest method to verify the functionality of the system involves the use of an RS485-USB interface cable which, through the TRITON_SCAN program and the installation of a specific driver (the installation package is supplied with the machine), enables the control of the generator by emulating a VirtualCom serial communication port through a USB port of the control PC.

In all the proposed models, with the exception of TRITON_SCAN, the easy-to-use interface has everything needed to manage the most frequently used parameters in an ultrasonic tank:

- knob for immediate variation of the power (and other parameters, when the system is in programming mode);

- button for activating the solenoid valve for draining the liquid from the tank;

- START-STOP key for the ultrasound treatment;

- TIMER key;

- HOME key to access the parameter selection and programming mode;

- LCD display (backlit, with white characters on a blue background) for viewing the operating parameters.

If requested, it is possible manage a level sensor if the customer’s tank has such a sensor.

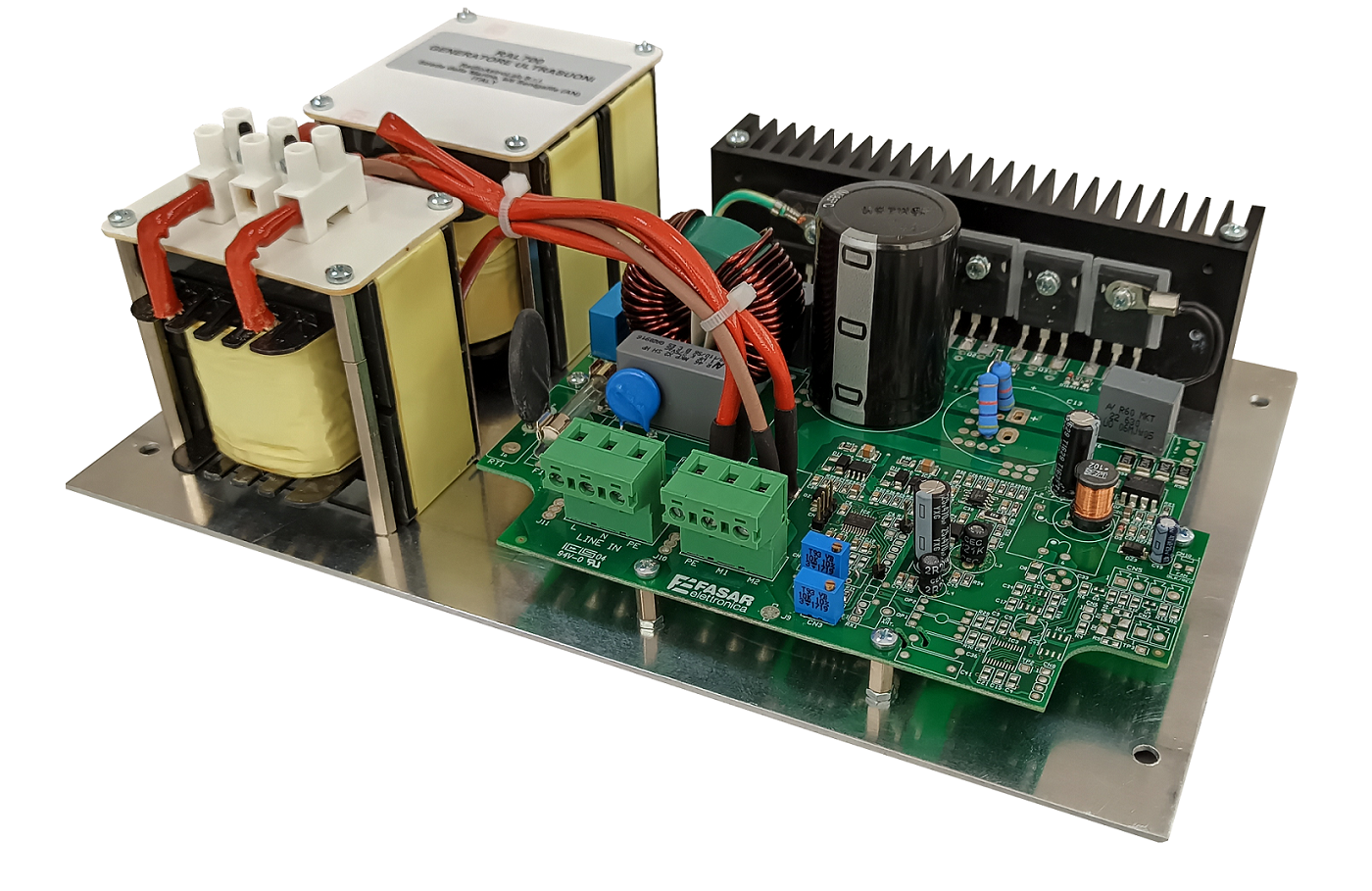

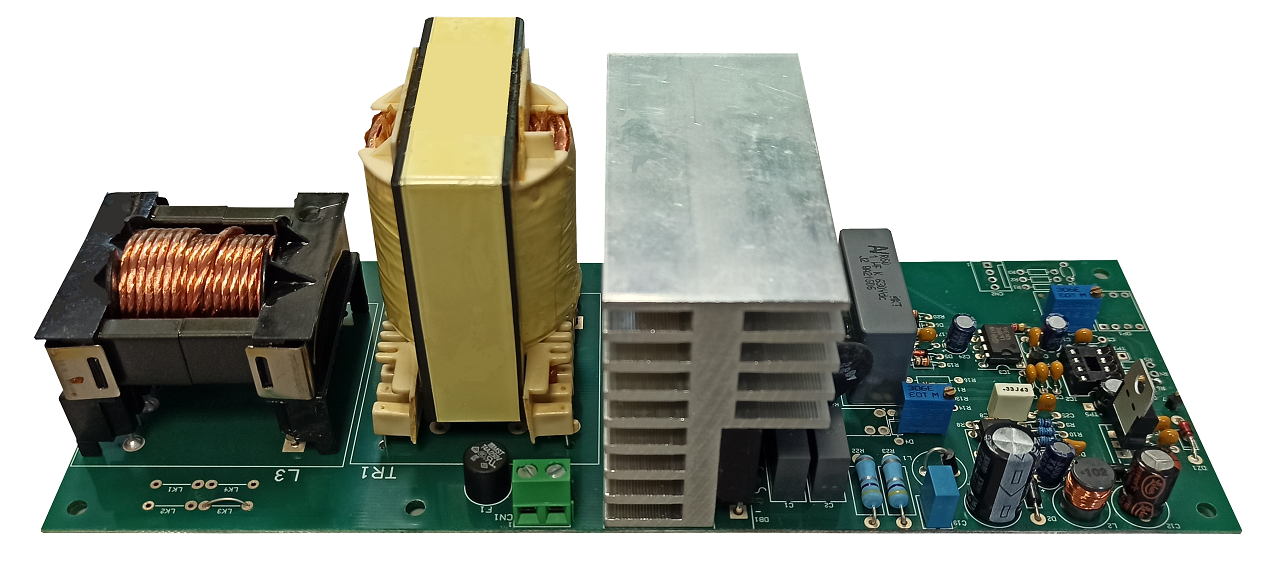

OPEN BOARD VERSION

Our power boards are also available in the open version, for tank manufacturers who want to independently arrange the layout of the board within their application, ensuring adequate ventilation. Once the transducer group (operating in the 22-60 kHz band) has been connected to the generator, it will be sufficient to power the system (230 Vac, 50/60 Hz).

Based on the required power, these two versions are available:

- RAL151 generator (max 400W with appropriate ventilation).

- RAL700 generator (max 2000W with appropriate ventilation).

Both boards have two trimmers for frequency and power regulation.